Aqua Freed® & Aqua Gard® Case Studies

Successful Rehabilitation of More Than 8,000 Water Wells Worldwide

The AQUA FREED® well rehabilitation process has been extremely successful in restoring lost capacity to more than 8,000 wells worldwide since 1987. Below is a small sampling of before and after results from the AQUA FREED® well rehabilitation and AQUA GARD® preventative well maintenance processes.

AQUA FREED® & AQUA GARD® are protected by US/foreign patents and insured against infringement by IPS.

AQUA FREED®

Case Study 1

Client: City of Tampa Water Dept.

Location: Tampa, FL

Well ID: TAP-1

Constructed: 2017

Well Depth: 530 ft bgs

Well diameter: 12-inch

Well construction: Bedrock open borehole

Open bore length: 250 feet

Original yield: 1.04 MGD

TAP-1 is a public water supply ASR recovery well that was installed in the Upper Floridan Aquifer (UFA) in 2017. The well is operated seasonally in the winter and spring seasons to supplement the surface water reservoir that supplies the City of Tampa. Water is injected into the UFA through an adjacent ASR well and withdrawn from TAP-1. Operation during the 2021 year showed a decline in the capacity of TAP-1 by half of its original permitted capacity of 1.04 million gallons per day (MGD).

In February 2022, the pumping system in the well was removed and the well televiewed to assess its condition. The video revealed that the well was fouled with a bacteria film and mineral scale. An Aqua Freed® CO2 treatment was performed by completing two injections in the open bore section of the well and then thoroughly developed by air lift pumping. A post-development well video was completed and revealed that the borehole and prominent fractures and pore openings in the carbonate bedrock were significantly cleaner than before the Aqua Freed® treatment.

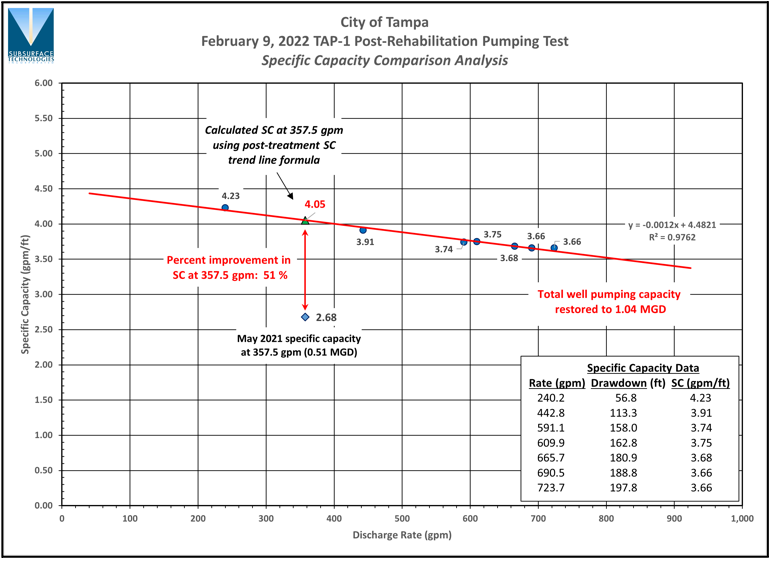

After the well was fully rehabilitated and flushed, the performance of the well was assessed by conducting a step-drawdown pumping test at seven different pumping rates. The resulting specific capacities were plotted and a trend line fitted to the data. Comparing the pre-rehabilitation specific capacity to the post-rehabilitation test trend line indicated an improvement of 51 percent at the maximum pre-rehab pumping rate of 0.51 MGD. In addition, the testing showed that the total pumping capacity of the well was fully restored to 1.04 MGD. The well was returned to service and continues to serve the City of Tampa Water Department as an aquifer storage recovery well.

Pre-treatment well condition

Post-treatment well condition

AQUA FREED®

Case Study 2

Client: Liberty Utilities

Location: Apple Valley, CA

Well ID: Apple Valley Well #34

Constructed: 1989

Well Depth: 400 ft bgs

Well diameter: 16-inch

Well construction: Gravel-packed, slotted pipe screen

Screen length: 250 feet

Screen material: Steel

Original yield: 1,500 gpm

Apple Valley Well #34 is a public water supply well that was installed in a weathered granite aquifer in 1989. The well operated for many years without problems until it started experiencing water quality problems in 2020. The well was rehabilitated several times using conventional methods and chlorination to remediate the positive bacteria detections. After additional positive detections and repeated flushings followed by positive detections of bacteria, the well was taken offline. The loss of production from the well was a serious concern to Liberty Utilities so Subsurface Technologies, Inc. was contracted to provide an Aqua Freed® well rehabilitation service to the well to thoroughly clean the well, the gravel pack, and the water-bearing zones in the granite aquifer.

In November 2022, the pumping system in the well was removed and the well televiewed to assess its condition. The video revealed that many of the slots in the well were fouled with sediment and mineral scale. It was suspected that the gravel pack and fracture zones in the granite aquifer may also be fouled and contain substrate to support persistent bacteria growth. An Aqua Freed® treatment with two injection zones was performed and then the well was thoroughly flushed to remove all debris and sediment loosened by the treatment. A post treatment well video revealed that the slots and gravel pack were much cleaner than before the treatment.

After the well was video surveyed, the well performance was tested and the pumping system was reinstalled in the well in early January 2023. Water quality testing conducted after the completion of the Aqua Freed® treatment and startup of the well resulted in negative bacteria detections and the well was returned to service to help meet the water supply demands of Liberty Utilities customers.

Pre-treatment well condition

Post-treatment well condition

AQUA FREED®

Case Study 3

Client: City of Redding, CA

Location: Redding, CA

Well ID: EW#23

Constructed: 2007

Well Depth: 410 ft bgs

Well diameter: 16-inch

Well construction: Gravel-packed wire-wrapped screen

Screen length: 140 feet

Screen material: Stainless steel

Original yield: 1,550 gpm

“And your work was fantastic! Nothing short of a miracle.” – Project engineer K. Bral, Jacobs

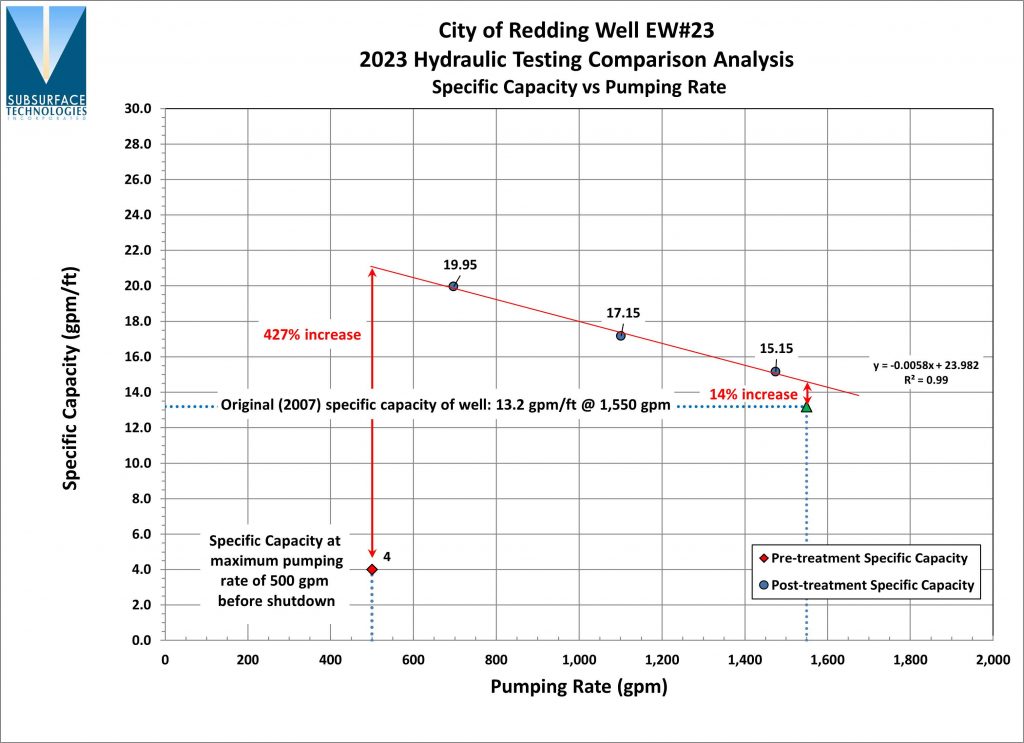

Redding Well EW#23 is a public water supply well that was installed in a stratified sand and gravel aquifer in the northern edge of the Central Valley. The well was a high producing well with a sustainable pumping rate of 1,550 gallons per minute (gpm) with a specific capacity of 13.2 gpm/ft at the time of its startup in 2007. Over time, the well yield declined to 500 gpm and a specific capacity of 4 gpm/ft until being taken offline to perform rehabilitation. Several attempts were made to rehabilitate the well using conventional methods and chemical treatments but with no success. As a last ditch effort, the City of Redding and its consulting engineers decided to use Subsurface Technologies Aqua Freed® well rehabilitation process.

In February 2023, the well was televiewed to assess its condition. The video revealed that the well screen had some biofouling, but most of the screen slots were partially open. The well was then brushed in preparation for the Aqua Freed® treatment. Two Aqua Freed® injections were performed in the well and then the well was flushed and developed thoroughly by dual swab airlift to remove all loosened biofilm and sediment from the well. A post-treatment video was performed and revealed a much cleaner screen. A relatively large amount of sediment was removed from the well suggesting that the well had a significant siltation problem in addition to partial biofouling. The source of the sediment was suspected to be finer units in the stratified deposits that infiltrated into the water-bearing zones and choking off flow to the well.

A post-treatment step-drawdown pumping test was performed and resulted in the specific capacity of the pre-shutdown pumping rate of 500 gpm to increase by 427 percent. In addition, the specific capacity of the original yield rate of 1,550 gpm increased by 14 percent. Not only had the Aqua Freed® treatment restored the pumping capacity of the well, but it also increased the overall production capacity of the well. A new pump system was installed by the City and the well was returned to service in March 2023.

AQUA FREED®

Case Study 4

Client: Velociti Services

Location: Atlantic City, NJ

Well ID: Well #5

Constructed: 1982

Well Depth: 164 ft bgs

Well diameter: 12-inch

Well construction: Gravel-packed wire-wrapped screen

Screen length: 40 feet

Screen material: Stainless steel

Original yield: 554 gpm

Atlantic City Airport Well #5 is a public water supply well that was installed in a sand and gravel aquifer in Egg Harbor Township, New Jersey. Well #5 was a high producing well with a sustainable pumping rate of 500 gallons per minute (gpm) and a specific capacity of 22.3 gpm/ft at the time of its initial testing in 1982. After years of service, the well yield declined to a rate less than the desired pumping rate needed to supply the needs of the supply system and was taken offline in early 2023 to perform a rehabilitation using Subsurface Technologies, Inc.’s Aqua Freed® technology.

In January 2023, the well was televiewed to assess its condition after removing the pumping equipment. The video revealed that the well screen had a heavy mineral encrustation and iron biofouling which increased with depth in the screen interval. The well was then brushed in preparation for the Aqua Freed® treatment. An Aqua Freed® injection was performed by injecting liquid and vapor phase CO2. The well was then flushed and developed thoroughly by swabbing and simultaneous airlift pumping to remove all loosened biofilm, mineral encrustation, and sediment from the well. A post- treatment video televiewer survey was then performed revealing a clean and unobstructed screen.

A post-treatment step-drawdown pumping test was performed and resulted in a specific capacity of 31.65 gpm/ft at the desired operational pumping rate of 500 gpm. The linear trend line formula of the post treatment testing specific capacities was used to calculate a new specific capacity of 30.62 gpm/ft at the original yield rate of 554 gpm. Comparing that new result to the original 1982 specific capacity resulted in an increase of 37 percent in specific capacity. A new pump and motor was also installed and the well was then successfully sampled for disinfection confirmation. The well was then returned to service in March 2023 and continues to serve the water supply needs of the Atlantic City airport facilities.

Pre-treatment well condition

Post-treatment well condition

AQUA GARD®

Case Study 1

Client: Poweshiek Water Association

Location: Tama, IA

Well IDs: Angled Wells #1 and #2

Constructed: 2008

Well Lengths: 150 ft

Well diameters: 12-inch

Well construction: Gravel-packed, slotted pipe screen

Screen lengths: 20 feet

Screen material: Steel

Original yields: 250 gpm

By Matt Tapkin, Director of Poweshiek Water Association:

“In 2008, Poweshiek Water Association (PWA) constructed a new treatment plant and wellfield. PWA specified that Aqua Gard® was to be installed on these wells based on the consistent success we enjoyed at our other vertical wellfield. After installing three new angle wells, it was determined that two of the three new wells were only a fraction of the design and flow rate anticipated. Subsurface Technologies, mobilized on extremely short notice, even though they were fully scheduled and through the use of Aqua Freed® CO2 injection, significantly improved the development of these wells. The overall result from this effort was a well capacity increase of between 90-100%. All other avenues for development had been attempted with little percentagebased increases in capacity with each attempt. Had we not been able to use Subsurface Technologies to aid in the development, PWA would have been faced with enormous costs to drill more wells and install the associated pipeline, etc. As far as PWA is concerned, this was a project saver both from a money and time perspective as we were starting a completely new and independent treatment plant, distribution system and well field with a new customer base relying on our water. The wells are serviced with Aqua Gard® and serviced annually, maintaining flow and efficiency at a significant cost reduction.”

Wellhead sealed during Aqua Freed® injection on Well #1

STI performing an Aqua Freed® injection on Well #2

AQUA GARD®

Case Study 2

Client: Veolia (USG)

Location: Merchantville, NJ

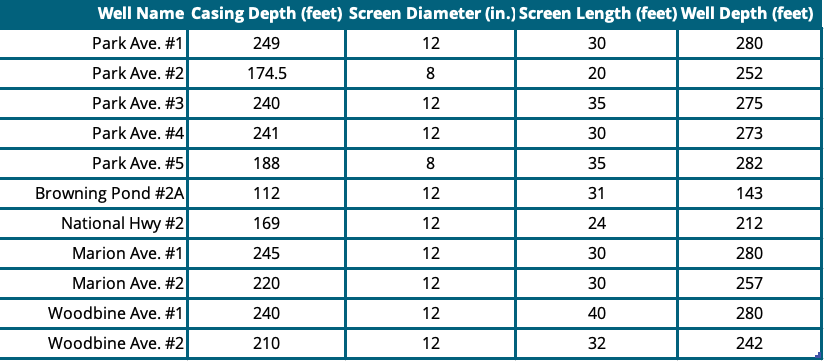

Eleven wells in the Merchantville water system, located in Pennsauken Township New Jersey, have been serviced for several years using Subsurface Technologies, Inc.’s (STI) Aqua Gard® well maintenance system to maintain the production performance of the wellfield. Prior to initiating the well maintenance program, each of the wells were rehabilitated using STI’s AquaFreed® dual-phase CO2 treatment technology in 2017 and 2018. The wellfield consists of screened wells with depths ranging from 143 feet below grade to as much as 282 feet below grade. Nine of the eleven wells have screens that are 12 inches in diameter while two wells have 8 inch diameter screens. The unconsolidated aquifer that they draw water from is a high yield aquifer and the wells yield several hundred gallons per minute (gpm), some exceeding 1,000 gpm. Table 1 is a summary of the well construction details of the eleven wells in the Merchantville wellfield that are serviced using the Aqua Gard® system.

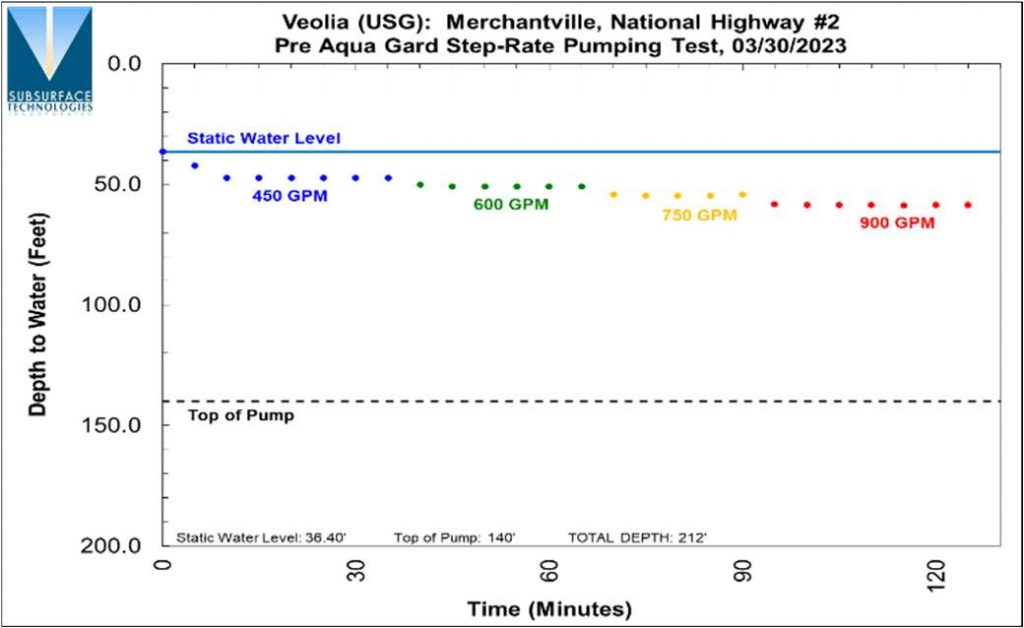

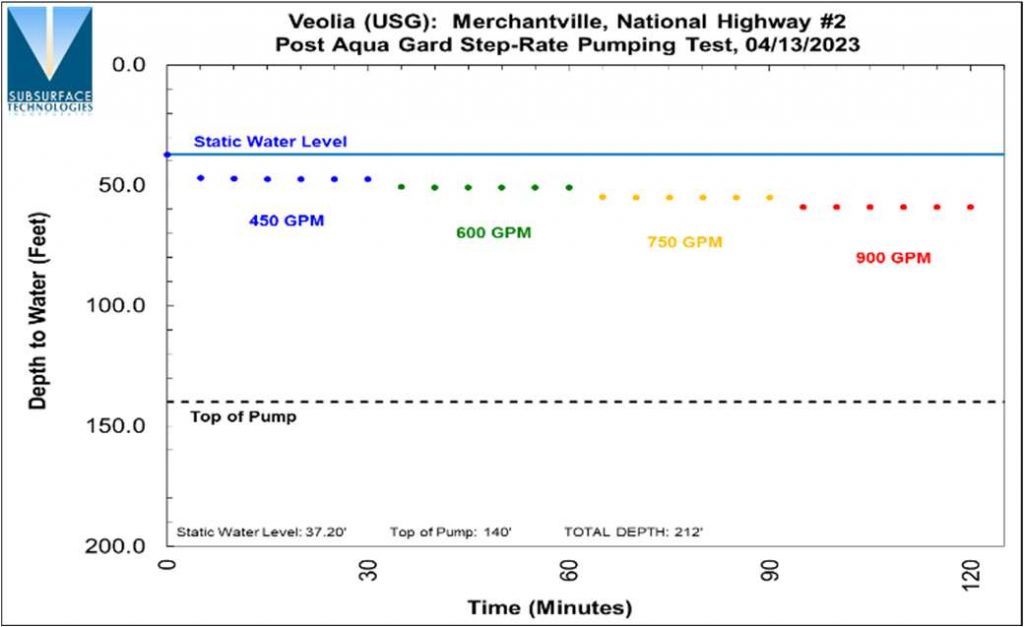

The wells in the system are maintained using the Aqua Gard® maintenance system and are treated annually to maintain the pumping performance of the wells and help keep the water quality at optimal levels. Prior to treatment, the wells are pump tested to measure their current performance (Figure 1). A post-treatment pumping test is then completed to determine the effectiveness of the Aqua Gard® treatment and allow for a comparison with the pre-treatment testing results (Figure 2). This data is also used to calculate specific capacities at various pumping rates and allow the long-term tracking of the performance trend of each of the wells.

Figure 1: Pre-treatment testing

Figure 2: Post-treatment testing

The data shown in Figures 1 and 2 reveals that the well National Highway #2 performed similarly before and after the treatment in terms of drawdown for each pumping rate and show that the pumping performance level is being maintained for that well. This is a similar pattern of behavior seen in the wells in the system and shows that, with routine Aqua Gard® maintenance, the wells can operate at a similar operational water level without any significant decline in pumping rate.

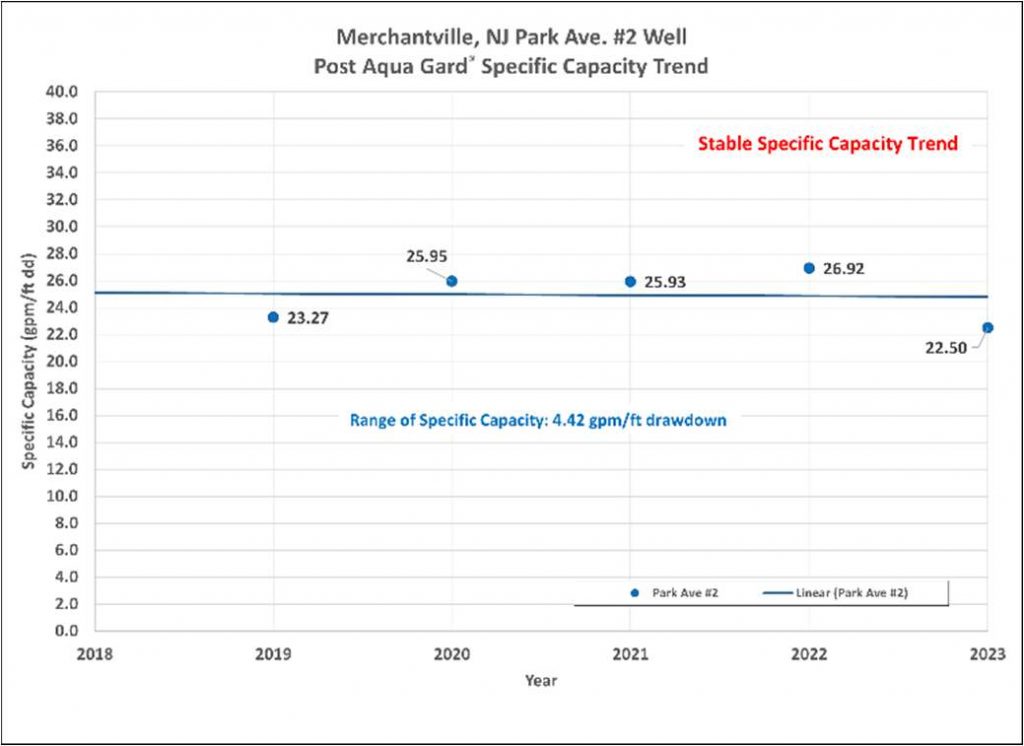

Figure 3

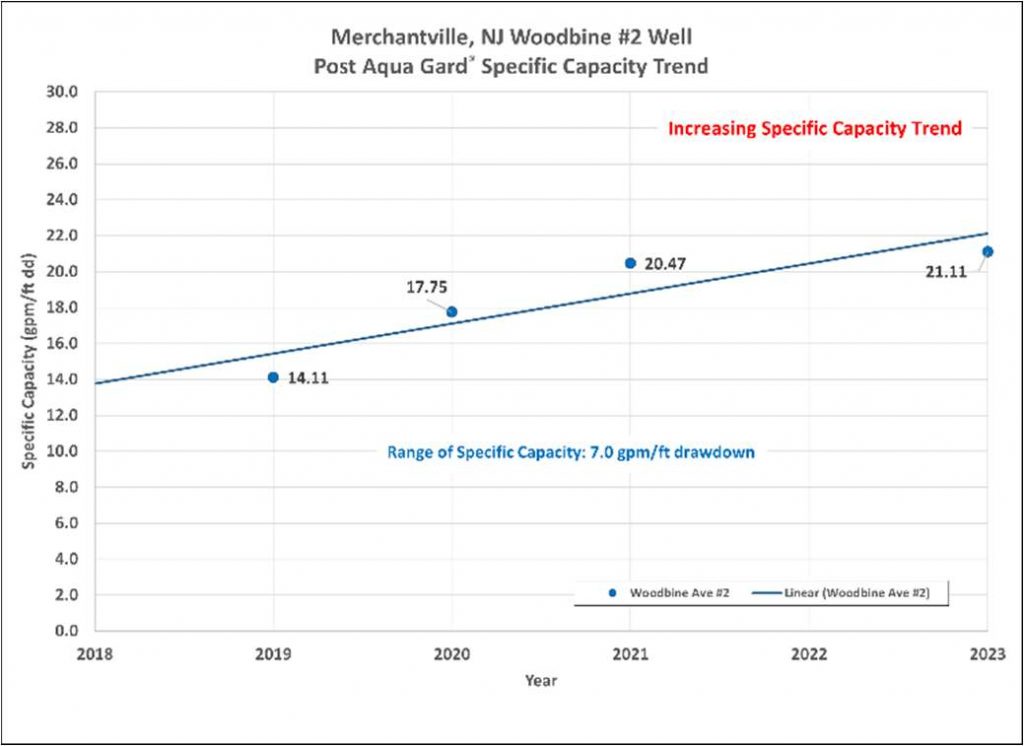

Figure 4

Figures 3 and 4 are plots of two example wells in the Merchantville system that display positive post treatment specific capacity trends that are indicative of the benefits of Aqua Gard® on maintaining pumping capacity. Figure 3 shows that over five years of Aqua Gard® treatments, the specific capacity of the Park Ave. #2 well was stable with a range in specific capacity of only 4.4 gpm/ft over that period. Figure 4 shows the post treatment specific capacity trend for the Woodbine #2 well which not only was maintained but continued to improve slightly year-to-year in four years of Aqua Gard® treatments. The specific capacity of the well after performing Aqua Gard® treatments increased by as much as 7 gpm/ft over the four year period.

Aqua Gard® has demonstrated its ability to maintain the pumping capacities of the wells in the Merchantville, New Jersey system. Subsurface Technologies, Inc. continues to maintain the Merchantville well field with Aqua Gard® on an annual basis, providing more efficient pumping operations, reducing energy costs, and allowing the wells to perform at there best ability to meet the water supply demands of the community.

Aqua Freed® | Process | Advantages | Case Studies | pdf Brochure | Request for Quote